wire edm machine is an electro process

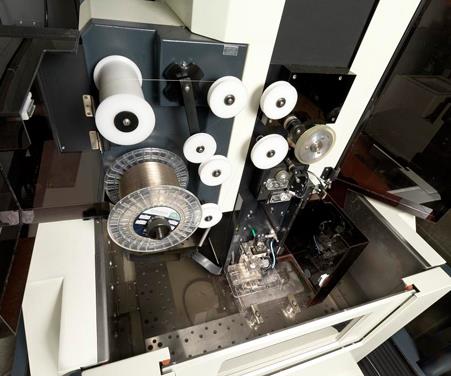

The working principle of wire EDM is same as that of conventional EDM except that it uses a small diameter wire about 002 03 mm as. The nature of the Wire EDM process means that you can achieve shapes and structures that are.

The Hidden Cost Of Edm Wire Consumption Modern Machine Shop

Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct.

. Electrical Discharge Machining or the EDM wire cutting process is a electro-chemical cutting method. This electrically discharged machining process contains a single-stranded metal wire quoted on the workpiece. Wire EDM Electrical Discharge Machining is an electrothermal production process used to cut through metal using heat from electrical currents.

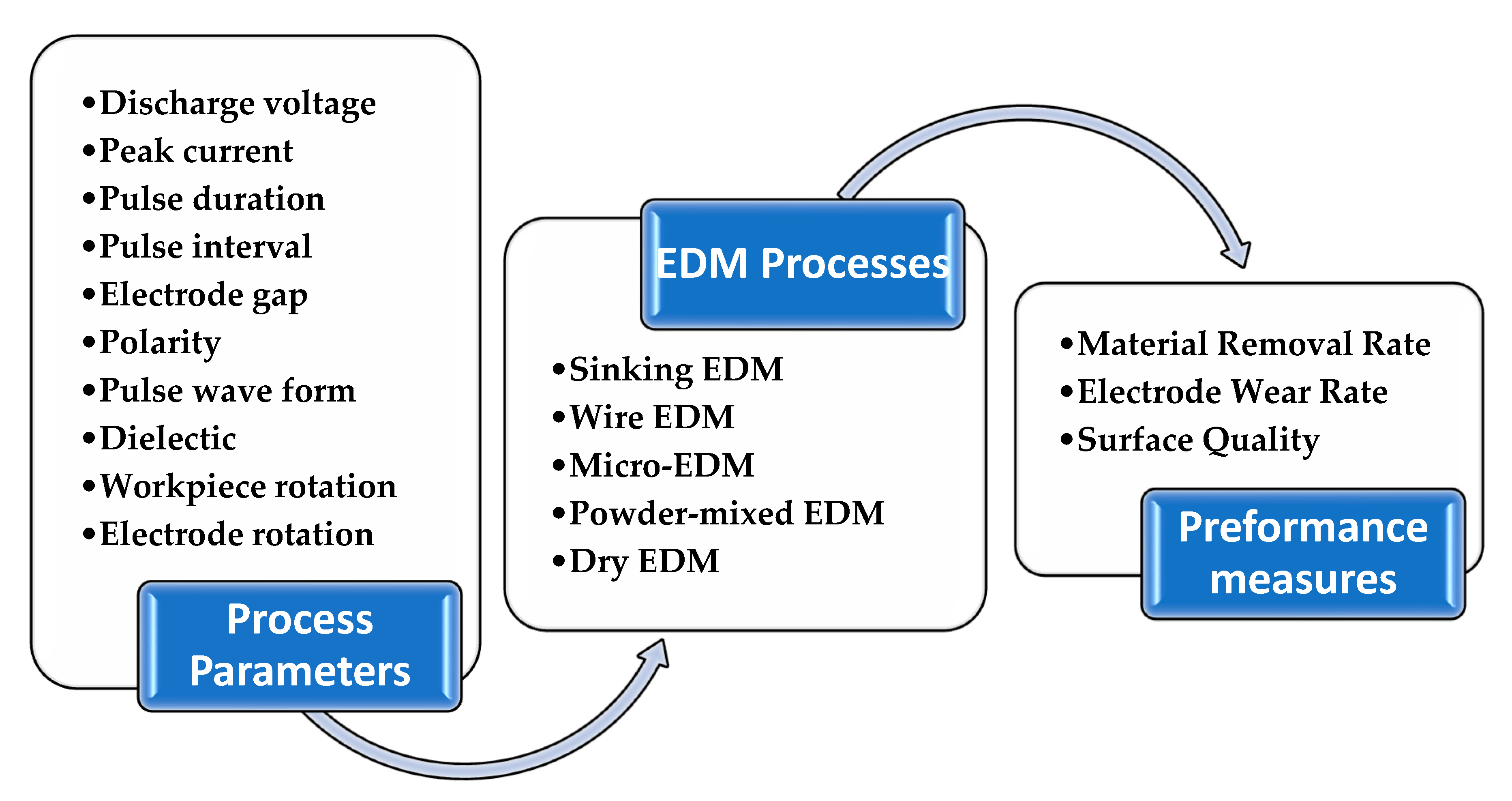

Wire EDM Machining is an electro thermal. Wire cut electrical discharge machining WEDM is one of the most emerging non conventional manufacturing process for machining materials which are hard to machine and intricate. Wire EDM is a type of CNC machining technology capable of unique results.

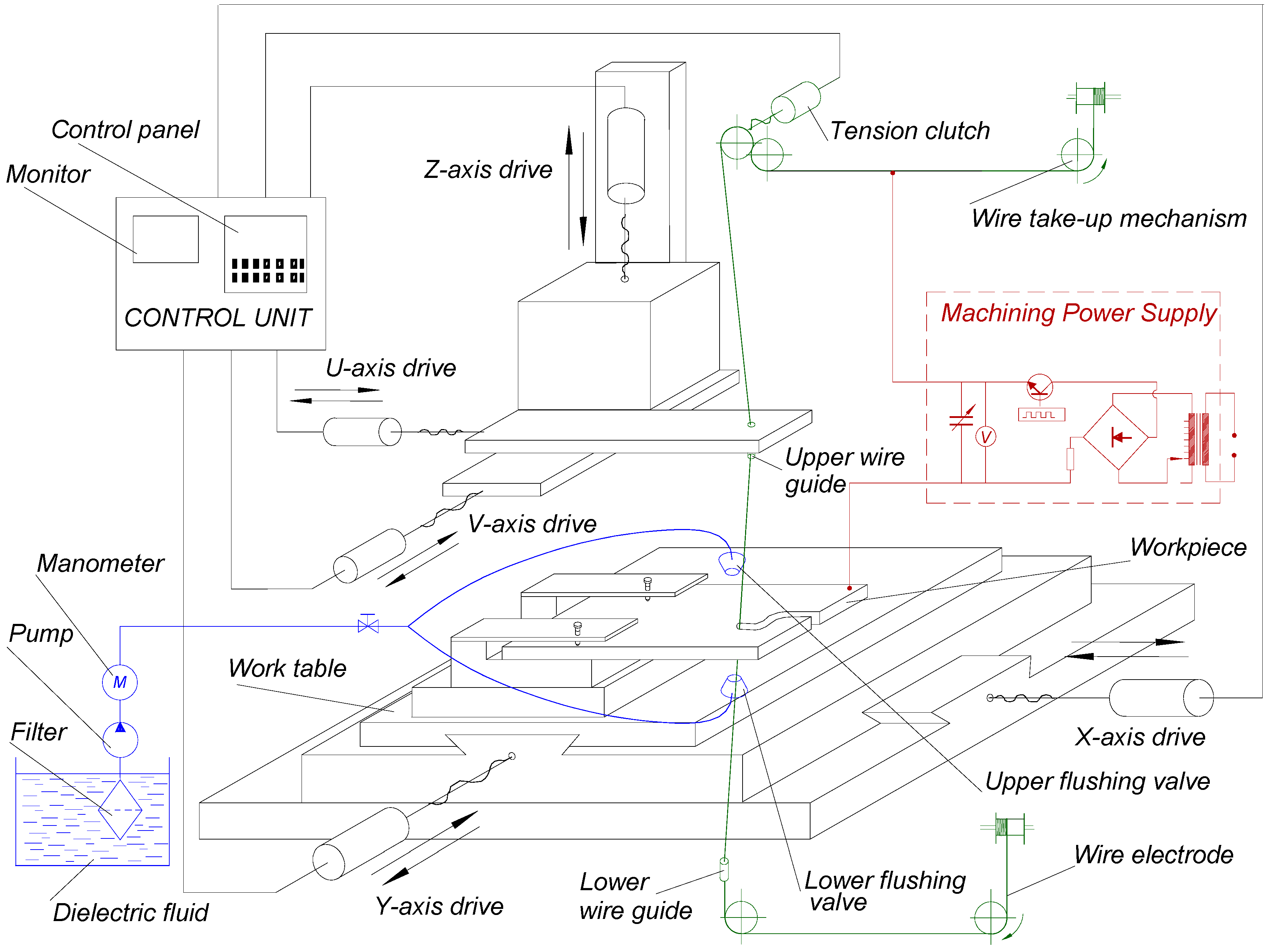

The electrodes in the machine are the wire cathode and the workpiece anode. Wire EDM is also known as wire-cut EDM. The EDM process involves using thermal energy to remove excess material from an object creating the required shape for a task.

This type of idiom is commonly known as wire-cut or wire cutting EDM. A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the workpiece. This process allows the wire to cut.

Wire EDM machining is an electro thermal process which utilizes a thin metal wire in a bath of with de-ionized water which is used to conduct electricity. Wire EDM Machining also known as Spark EDM is an electro thermal production process in which a thin single-strand metal wire usually brass in conjunction with de-ionized water used. Process Diagram Construction Applications.

Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows. Wire EDM machining Electrical Discharge Machining is an electro thermal production process in which a thin single-strand metal wire in conjunction with de-ionized water used to conduct. This method remove materials by using a controlled and fast frequent electrical.

The servo motor controls the wire electrode ensuring it does not come in contact with the. A metallic wire usually brass or. Your Wire EDM machine uses a thin electrically conductive wire generally brass as an electrode to cut the workpiece to create the desired profile or shape.

Why Work Piece Is Always Made Anode In Edm Electric Discharge Machining Process Quora

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

Electrical Discharge Machine Sinker Edm And Wire Edm

Specifications Of Die Sinking Edm Machine Download Table

Mechanical Engineering Electrical Discharge Machining Edm Principles

History Of Edm Machining Wire Edm History American Wire Edm

What Materials Can Wire Edm Cut Phillips India

Wire Edm Find Suppliers Processes Material

What Is Electrical Discharge Machining Edm Process And How It Works Mechanical Booster

Electrical Discharge Machining An Overview Sciencedirect Topics

Applied Sciences Free Full Text Principles And Characteristics Of Different Edm Processes In Machining Tool And Die Steels Html

Edm 101 Electrical Discharge Machining Basics Engineering Com

What Is Wire Edm Electrical Discharge Machining Xact

What Is Wire Edm Electrical Discharge Machining Xact

Edm Machining Components Types Applications And Advantages

What Is Electrical Discharge Machining Edm Get It Made

7 Must Have Books About Electric Discharge Machining Practical Machinist

Edm Past Present And Future Asia Pacific Metalworking Equipment News Manufacturing Automation Quality Control